Award-winning Mobile Technology

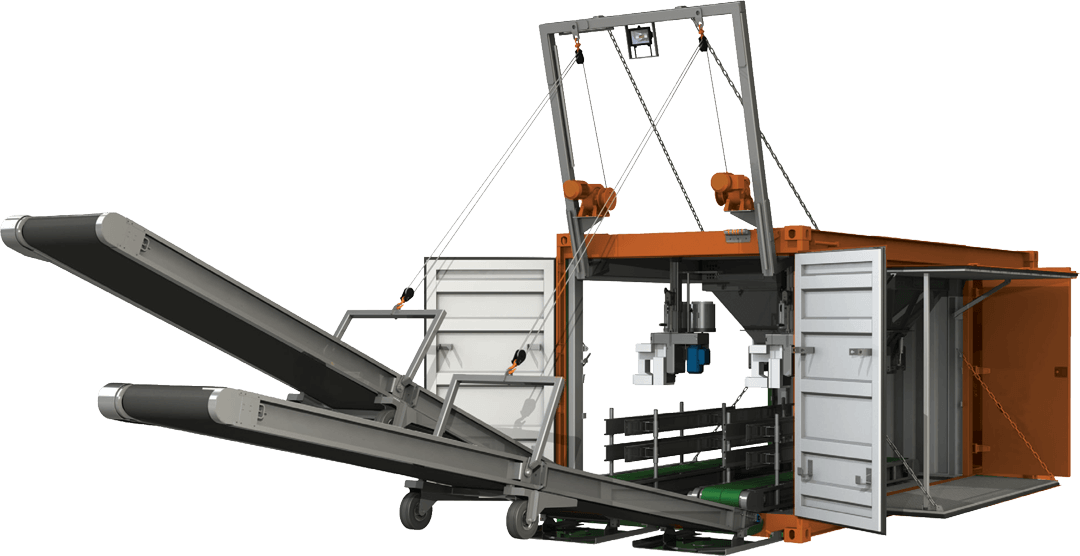

Unidade de ensacamento de linha dupla especialmente projetada e construída, alojada em um contêiner de aço de tamanho padrão ISO 20 pés 20' x 8' x 8' x 8' x 8' 6''.

Resumo do Desempenho

A unidade móvel de ensacamento compacM140 é uma unidade de ensacamento especialmente concebida e construída, alojada num contentor de aço de tamanho normalizado ISO de 20 pés, medindo 20' x 8' x 8' x 8'6" (lxwxh). O compacM140 pode ser manuseado com equipamento de manuseamento de contentores aprovado.

A compacM140 contém duas linhas de ensacamento lado a lado. Cada linha de ensacamento é projetada para fornecer ensacamento de produtos de fluxo livre com uma densidade de 0,70 a 1,25 toneladas por metro cúbico a uma velocidade de até 20 sacos por minuto por linha para sacos de 50 kg. Isto equivale a aproximadamente 140 MT por hora por máquina de ensacamento.

Actual performance will depend on the type of product that is bagged, the speed at which the equipment is fed with product, the efficiency of the operators and how quickly the bagged cargo is taken away from the machine.

Componentes da unidade de embalagem móvel

Descubra a tecnologia por trás de nossos equipamentos.

UNBEATABLE WEIGHT ACCURACY

The COMPAC™ weighing system has duplex scales, each mounted on three OIML C3-rated load cells. This significant feature allows for continuous high-speed, accurate weighing as one scale can be filling a bag whilst the second scale continues with the next weighment. The signal from the load cells is analysed 1,600 times per second, providing the controller with accurate control of each weighment. This allows the system to identify variations in the product such as particle size, consistency and flow characteristics and adjust the weighing formula automatically. Vibration and other mechanical interference are automatically eliminated by dynamic digital filtering.

The weighers are certified by the Dutch Weights and Measures (NMI). Certification no. T2971

Stainless Steel control box to house electronic components, controls and switch gear. Equipped with an internal cooling fan and filter.

Stainless Steel control box to house electronic components, controls and switch gear. Equipped with an internal cooling fan and filter.

Control panel for individual bagging lines. Features Penko Multi-channel Flex Control Panel with the following functionality; in-flight autocorrect, zero-tracking, tolerance control, dynamic digital filtering, true I/O architecture with 16 inputs and 32 outputs per line, password-protected calibration and LED touch screen.

Direct drive 2-piston compressor with wall-mounted air tank. The air tank has a 250-litre capability, manual drain, over-pressure safety valve and pressure gauge. The compressor has a working pressure of 5-6 bar and direct online start.

High-speed stitcher fitted to a stainless-steel roof-mounted, height-adjustable column, complete with a conveyor control box. Features include; single needle double thread chain stitch, adjustable stitch length 7-10.5mm to suit all bag types, pneumatic operated thread cutter, low maintenance splash lubrication system, variable speed pulley and automatic actuation with an infra-red sensor.

High-speed stitcher fitted to a stainless-steel roof-mounted, height-adjustable column, complete with a conveyor control box. Features include; single needle double thread chain stitch, adjustable stitch length 7-10.5mm to suit all bag types, pneumatic operated thread cutter, low maintenance splash lubrication system, variable speed pulley and automatic actuation with an infra-red sensor.

Two Heavy Duty Stainless Steel belt conveyors - Slider bed type. Each is equipped with a maintenance-free drum drive motor with an anti-slip layer. Adjustable bag guiding boards ensure proper movement of the filled bag. The motor and tail pulley head are both equipped with stainless steel belt adjustments. Endless PVC belts ensure smooth movement.

Two Heavy Duty Stainless Steel belt conveyors - Slider bed type. Each is equipped with a maintenance-free drum drive motor with an anti-slip layer. Adjustable bag guiding boards ensure proper movement of the filled bag. The motor and tail pulley head are both equipped with stainless steel belt adjustments. Endless PVC belts ensure smooth movement.

Engineered for efficient access and safe maintenance, flagship COMPAC™ models have three integrated ladders for roof access. Seven door openings, enable easy access to all weighing lines whilst promoting safer working practices. In operational mode side doors increase the work area to a total of 16 sqm.

Engineered for efficient access and safe maintenance, flagship COMPAC™ models have three integrated ladders for roof access. Seven door openings, enable easy access to all weighing lines whilst promoting safer working practices. In operational mode side doors increase the work area to a total of 16 sqm.

Individual compartment to house compressor and control units as well as optional generator setup (if required). Stainless steel construction for all controls and switch gear, equipped with an internal cooling fan and filters.

NECTAR’S PROVEN BUILD QUALITY & TECHNOLOGY

Alongside significant savings in operational costs, Nectar’s build quality is designed with the highest-grade materials to withstand all dynamic loads — as well as the wear and tear of busy bulk terminals. Constructed of heavy gauge shot-blasted SA2.5 steel and coated with a unique blend of epoxy primers and finished with a distinctive orange polyurethane marine grade paint to protect against corrosive commodities and adverse weather conditions. Engineered for efficient access and safe maintenance, flagship COMPAC™ models have three integrated ladders for roof access.

Características

Opções adicionais

Por que selecionar equipamento de ensacamento néctar?

SOLUÇÕES DE ENSACAMENTO E LOGÍSTICA MEDIDA

PESOS E MEDIDAS HOLANDESES CERTIFICADOS

COBERTURA GLOBAL

140 TONELADAS MÉTRICAS POR HORA CAPACIDADE DE PROJETO POR UNIDADE DE ENSACAMENTO

PESOS PRECISOS +/-0,5%

DESEMPENHO GARANTIDO

IDEAL PARA CARGAS FREE-FLOWING QUE INCLUEM FERTILIZANTES, PULSOS, GRÕES, ARROZ, AÇÚCAR ETC.

SERVIÇO PREMIADO E PRODUTOS

Nossa gama completa de equipamentos de ensacamento

O néctar oferece uma escala detalhada do equipamento do ensacamento, que pode ser personalizado a suas exigências.

Ideal para seco, fluindo livre, não-Bridging commodities, nossas máquinas premiadas fornecer precisão de peso imbatível. Eles são montados e fabricados para aderir às mais rigorosas normas europeias de segurança

FALE CONOSCO

1 Ashton Gate, Ashton Rd.

Harold Hill, Romford

Essex. RM3 8UF

<i class="fas fa-at"></i> commercialteam@nectar.co.uk

Oportunidades de emprego: HR@nectar.co.uk

<i class="fas fa-phone"></i> + 44 (0) 1708 386555

* indica um campo obrigatório