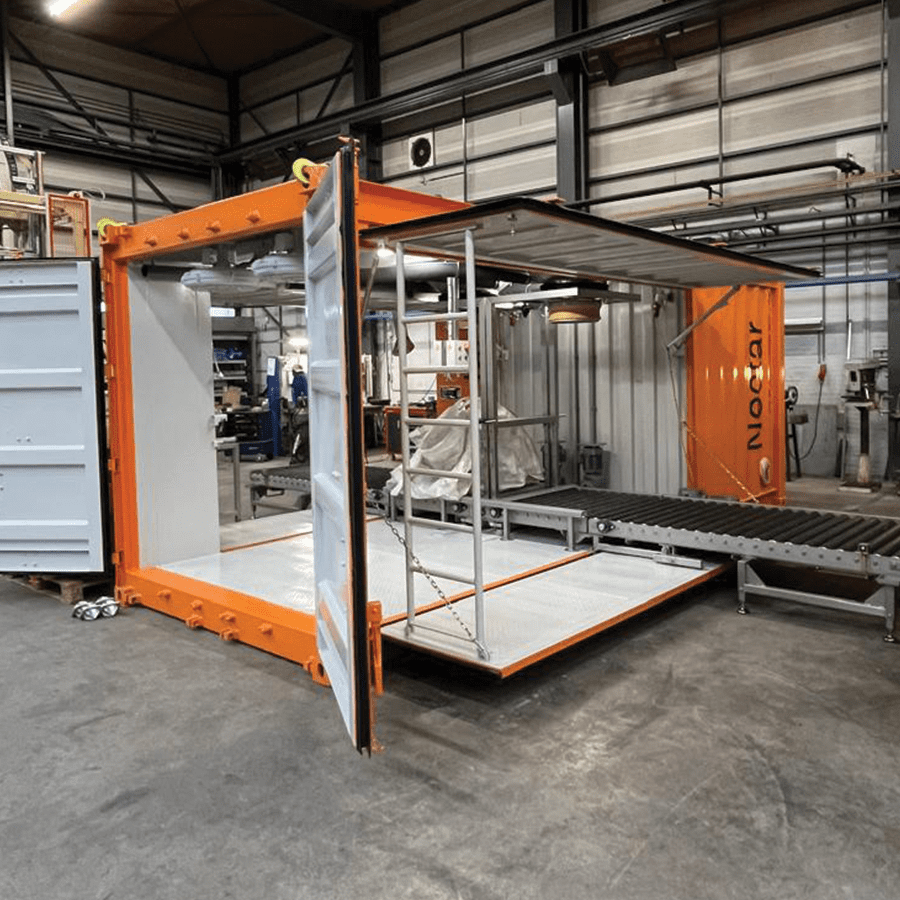

Specialist Bagging Unit for XL and Big Bags.

Compac XL 120 is a free-standing two-line big bag installation designed to handle up to 120 mt of cargo per hour, discharging into large XL 1000 kg bags. Designed to handle free-flowing dry bulk goods.

Performance Data Summary

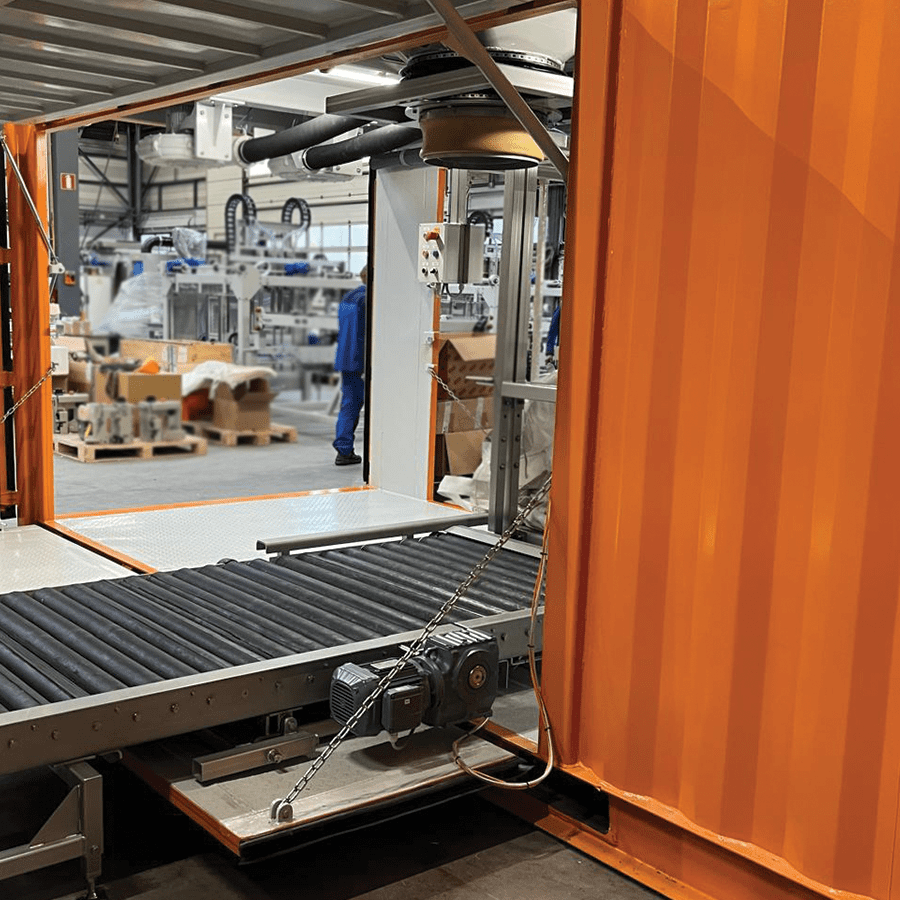

The flexible design of the Compac XL 120 allows for complete compatibility with a variety of applications and requirements. Employ as bagging facilities for an existing plant, in port warehouses, for inland locations, dockside storage depots, and for direct discharge of bulk products from vessels. All Compac bagging units are constructed to offer flexibility and manoeuvrability for all your port requirements.

Compac XL can bag free-flowing, non-bridging granular products with a minimum density or 0.7 ton per cubic meter and a maximum size or 25mm.

It contains two stainless steel pneumatic operated dosing valves, one inflatable bag spout, One high-speed fan for bag inflation before filling, One weighing platform complete with a motorized roller table, one motorised roller table extension of 2.5 meters and one control panel.

Features

Additional Options

Why Select Nectar Bagging Equipment?

TAILOR-MADE BAGGING AND LOGISTICS SOLUTIONS

DUTCH WEIGHTS AND MEASURES CERTIFIED

GLOBAL COVERAGE

140 METRIC TONNES PER HOUR DESIGN CAPACITY PER BAGGING UNIT

ACCURATE WEIGHTS +/- 0.5%

GUARANTEED PERFORMANCE

IDEAL FOR FREE-FLOWING CARGOES INCLUDING FERTILIZERS, PULSES, GRAINS, RICE, SUGAR ETC.

AWARD WINNING SERVICE AND PRODUCTS

Our Full Range of Bagging Equipment

Nectar offers a comprehensive range of bagging equipment, which can be customized to your requirements.

Ideal for dry, free flowing, non-bridging commodities, our award-winning machinery provide unbeatable weight accuracy. They are fitted and manufactured to adhere to the strictest European safety standards

CONTACT US

1 Ashton Gate, Ashton Rd.

Harold Hill, Romford

Essex. RM3 8UF

commercialteam@nectar.co.uk

Job Opportunities: HR@nectar.co.uk

+44 (0)1708 386555

* indicates a required field